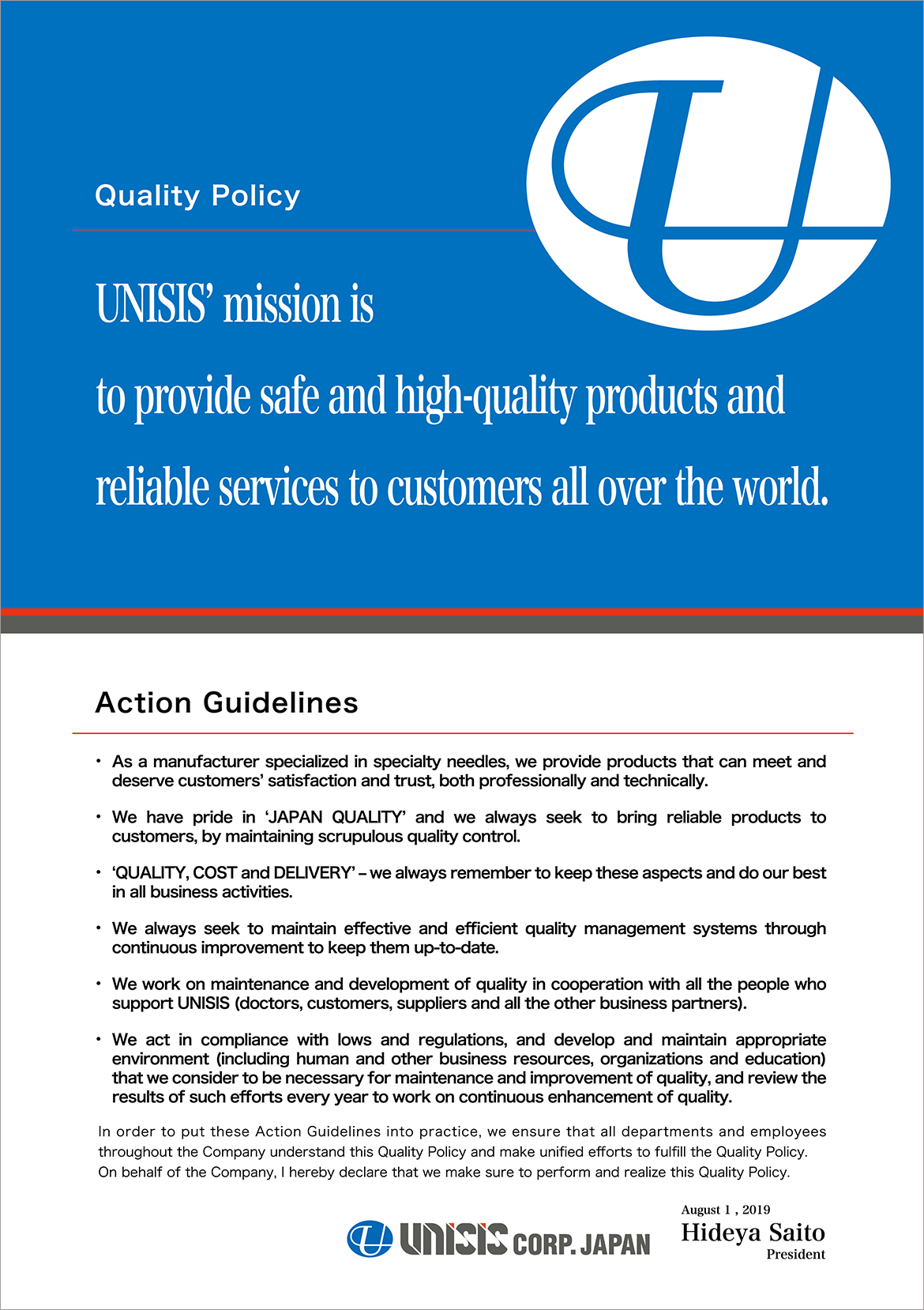

QUALITY POLICY

UNISIS is committed to provide safe and high-quality products

and reliable services to customers all over the world.

We gain our customers' trust through quality products.

Our mission as a global medical device manufacturer as well as the leading manufacturer of

specialty needles is to provide customers with high-quality products.

We always keep this fundamental mission in mind when responding to customer needs and

providing reliable quality of our products and services.

| 1989/10 | Obtained import license for medical devices in Japan (BBY6379 for the Tokyo office) |

|---|---|

| 1994/2 | Obtained manufacturing license for medical devices (11BZ0588 for the Koshigaya factory) |

| 1995/11 | Obtained Japanese accreditation in Good Manufacturing Practices (GMP) |

| 1996/09 | US Food and Drug Administration registration (FDA Facility Registration No. 9014974/USA) |

| 1997/06 | Obtained accreditation of ISO9002/ISO13488 audited by TUV Rheinland |

| 1999/01 | Obtained license for manufacturing veterinary appliances (16 veterinary manufacturer No.344 for Koshigaya factory) |

| 2003/06 | Obtained accreditation of ISO9001/ISO13488 audited by TUV Rheinland |

| 2004/01 |

Obtained manufacturing license for medical devices (11BZ6041 for Saitama Plant) Obtained manufacturing license for veterinary appliances (16 veterinary manufacturer No. 457 for Saitama factory) |

| 2004/07 | Obtained accreditation of ISO9001/ISO13485 audited by TUV Rheinland |

| 2005/12 | Obtained CE marking audited by TUV Rheinland |

| 2009/07 | Obtained Medical Device Manufacturer Permit (11BZ200120:at Logistics/sterilization center) |

| 2010/05 | Renewed CE marking that covers spinal needles, a Class III device |

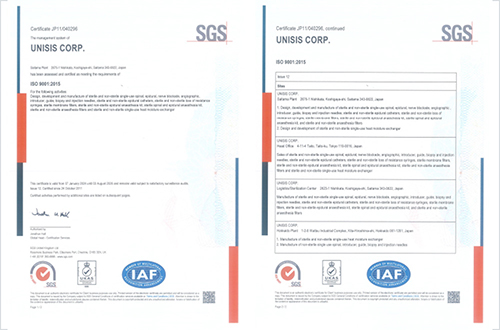

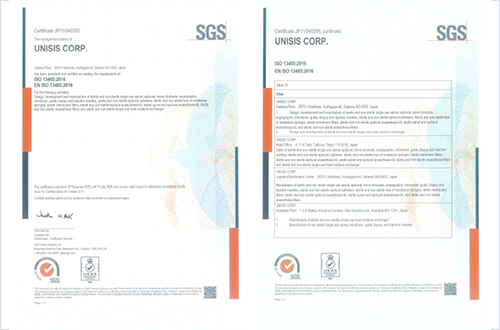

| 2011/10 | Notified Body for ISO9001/ISO13485 registration changed to SGS |

| 2012/05 | Notified Body for CE Marking (EU) registration changed to SGS |

| 2014/10 | Obtained 510(k) clearance for Spinal Anesthesia Needle |

| 2015/01 | Obtained 510(k) clearance for Epidural Anesthesia Needle and Nerve Blockade Needle |

| 2019/02 | Obtained CE marking for Atraumatic Microneedle audited by SGS |

Unisis received ISO9002:1994 and ISO13488:1994 accreditation in 1997. The company subsequently developed an internationally recognized quality management system (QMS) to earn the trust of customers worldwide.

Accreditation was upgraded to ISO9001:2015 and ISO13485:2016.

Our internal QMS was also made more stringent as appropriate for a medical device manufacturer.

We pledge to continue the upcompromising pursuit of excellence in response to customer demand for quality. Our confidence in that quest is based on the satisfaction, evaluation, and trust of our clients.

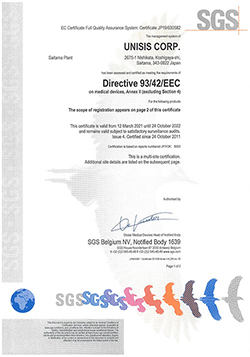

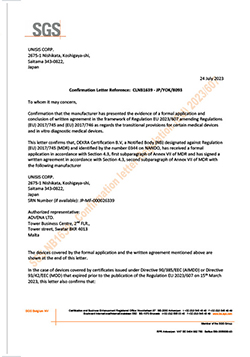

CE Marking

According to Regulation (EU) 2023/607 amending Regulations (EU) 2017/745, the transitional period for MDR and the validity of certificates under Directive 93/42/EC (MDD) have been extended.

| Device | Extended validity |

|---|---|

| All Class lll devices | 31 December 2027 |

Class ll b devices, Class ll a devices and Class ls devices |

31 December 2028 |

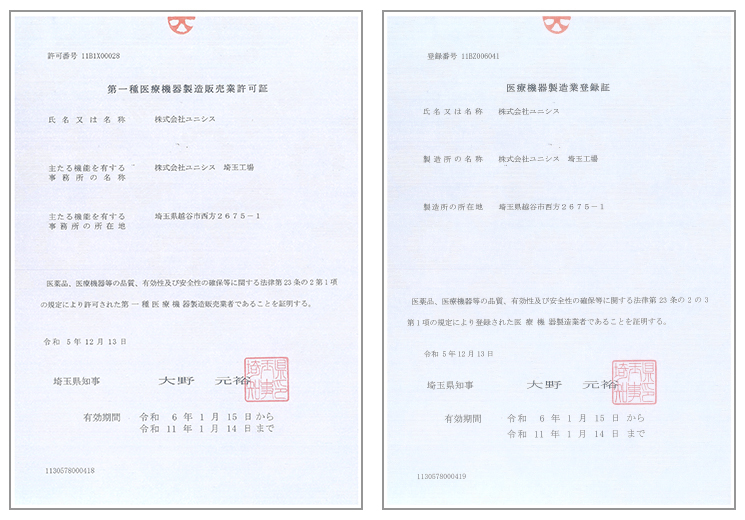

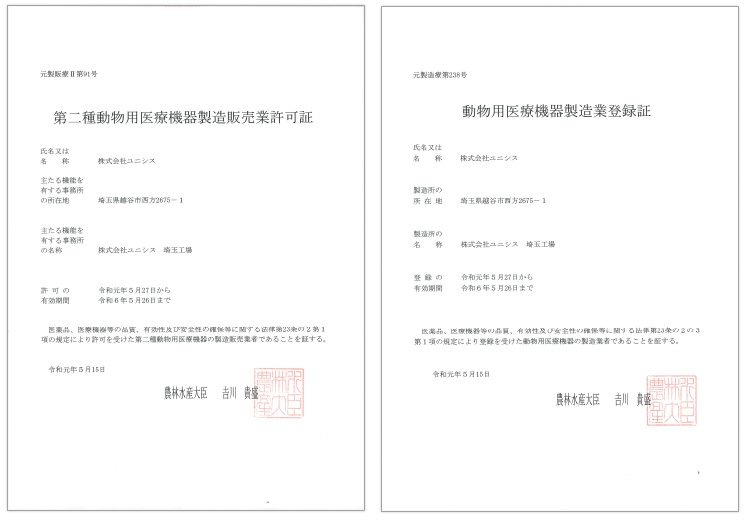

First-Class Medical Devices Marketing License /

Medical Devices Manufacturing License

(Saitama Factory, Unisis Corporation)

Second-Class Medical Devices for Veterinary

Use Marketing License /Medical Devices for Veterinary Use

Manufacturing License (Saitama Factory, Unisis Corporation)

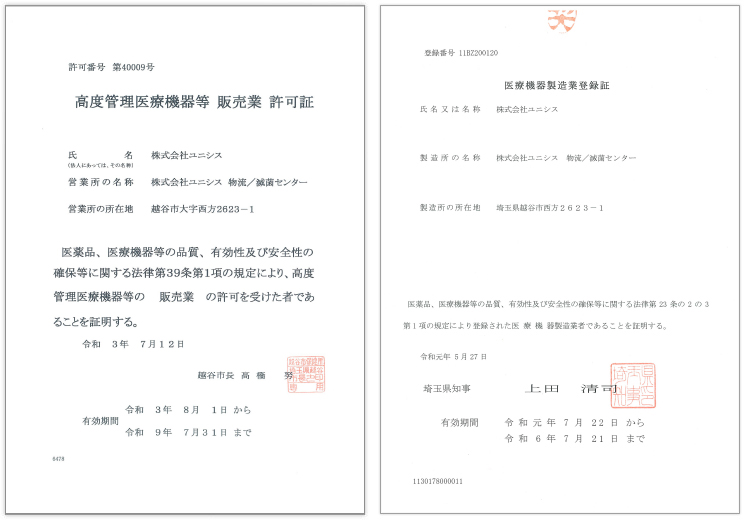

Specially Controlled Medical Devices Sales License /

Medical Devices Manufacturing License

(Logistics/Sterilization Center, Unisis Corporation)

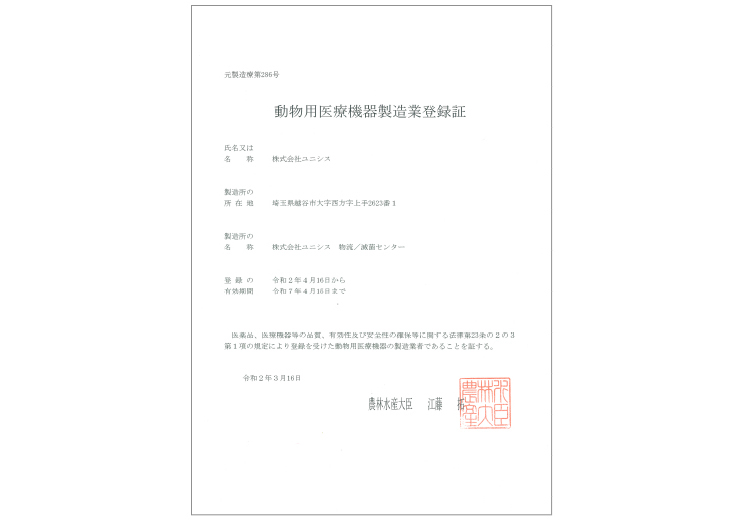

Medical Devices for Veterinary

Use Manufacturing License

(Logistics/Sterilization Center, Unisis Corporation)

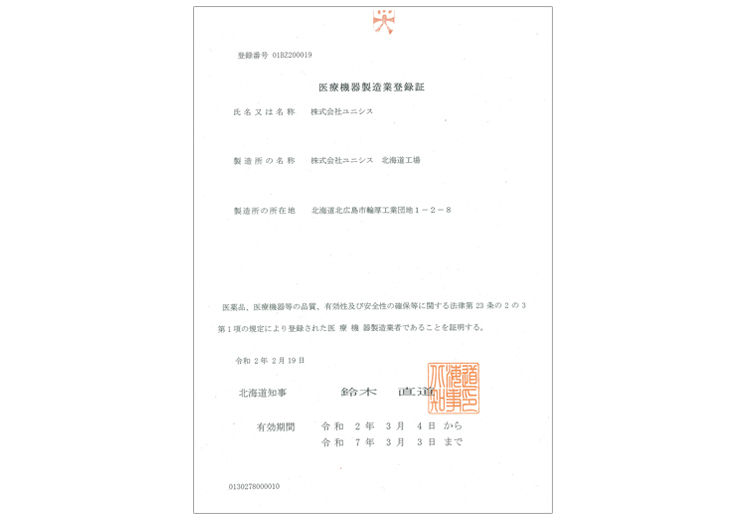

Medical Devices Manufacturing License

(Hokkaido Factory, Unisis Corporation)

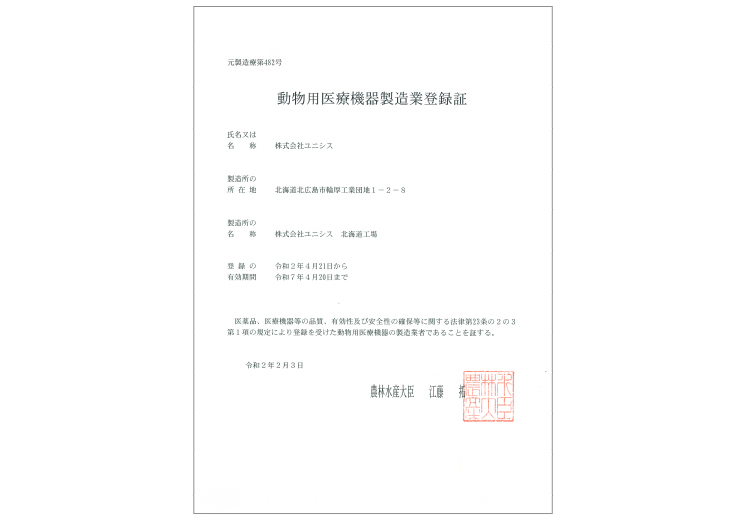

Medical Devices for Veterinary Use Manufacturing License

(Hokkaido Factory, Unisis Corporation)